When shopping for a suit, sticker shock is real. While you can walk into a department store and pick up something off the rack for a few hundred dollars, a custom suit might cost anywhere from $500 to well over $5,000. This price difference leaves many wondering: why are custom suits so expensive?

The answer goes beyond luxury. Every custom suit involves skilled craftsmanship, quality materials, personalized service, and hours of detailed work that justify the price.

This guide explains what makes custom suits cost what they do, from the fabric to the fittings. You’ll see exactly where your money goes and whether it makes sense for you.

What Makes Custom Suits Cost More?

Fabric Quality

The fabric you choose has the biggest impact on price. Premium materials like fine wool, cashmere, silk, and linen cost much more than cheaper synthetic fabrics found in mass-produced suits.

How It’s Made

Suits sewn by hand with full-canvas & half-canvas construction take more time and skill to make. This method creates a suit that breathes better, lasts longer, and looks more natural on your body. It costs more than suits that are glued together or made entirely by machine.

Your Personal Choices

A custom suit is built around your exact measurements and body shape. The tailor creates a one-of-a-kind pattern just for you. When you add special touches like unique linings, custom buttons, or specific design details, the price goes up.

Time and Expertise

Making your suit takes time. The tailor needs to measure you carefully, conduct multiple fittings, and construct the suit piece by piece. Each fitting session and the tailor’s years of training add to what you pay.

The Tailor’s Experience

Tailors with strong reputations, well-known clients, or decades of experience charge more for their work. You’re paying for their skill and proven track record.

Quality Materials Throughout

The cost also covers what you don’t see—quality linings, pocket fabrics, and internal layers that make your suit more comfortable and help it last for years.

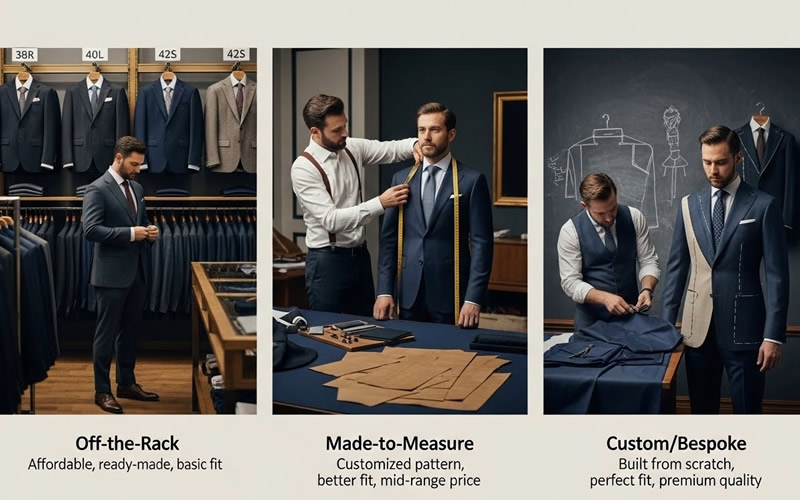

Custom vs Made-to-Measure vs Off-the-Rack Suits

Off-the-Rack Suits Cost & Other Details

Off-the-rack suits are ready-made suits you find hanging in stores. They come in standard sizes like 38R, 40L, or 42S.

How they work: Manufacturers make these suits in bulk using the same patterns for everyone. You walk in, try on a few sizes, pick what fits closest, and take it home.

The fit: These suits are designed to fit the “average” body type. If your body matches those standard measurements, you might get lucky. Most people need basic alterations like hemming pants or adjusting sleeve length.

The price: This is the most affordable option, typically ranging from $100 to $800.

Best for: Someone who needs a suit quickly, has a budget-friendly approach, or has proportions that match standard sizing.

Made-to-Measure Suit Costs & Other Details

Made-to-measure suits start with an existing pattern that gets adjusted to match your measurements.

How they work: A tailor takes your measurements and modifies a base pattern to fit your body. You choose fabric, lapel style, buttons, and other details. The suit is then made according to these specifications.

The fit: Much better than off-the-rack because it accounts for your actual measurements. However, the suit still follows a standard pattern structure with modifications rather than being built from scratch for you.

The price usually ranges from $500 to $2,500, depending on the fabric and the tailor.

Best for: Someone who wants a personalized fit and custom details without the highest price tag. Great middle ground between quality and cost.

Custom Suits Cost & Other Details

Custom suits are the highest level of custom tailoring. Everything is built from the ground up, specifically for you.

How they work: A master tailor creates a unique paper pattern based entirely on your body. Every measurement, every slope of your shoulder, and every detail is designed just for you. The suit is cut by hand and sewn mostly by hand. You’ll have multiple fittings where the tailor makes adjustments until everything is perfect.

The fit: This is as good as it gets. The suit is literally made for your body, and nobody else’s. It considers your posture, the way you stand, and even small differences between your left and right sides.

The price: Starts around $500 and can go well over $5000, depending on the fabric and the tailor’s reputation.

Best for: Someone who wants the absolute best fit, has specific style requirements, or invests in clothing that will last decades.

Quick Comparison

Off-the-rack: Grab and go, affordable, basic fit. Made-to-measure: Customized to your measurements, good fit, reasonable price. Bespoke: Made only for you, perfect fit, premium investment.

Fabric: The Foundation of Pricing

Fabric Quality and Grades

In a custom-made suit, you have a wide range of fabric choices. Not all wool is created equal. The custom suit cost varies dramatically based on fabric quality, which is measured by wool grades, thread count, and blend composition. Super numbers (Super 100s, Super 150s, etc.) indicate fiber fineness; higher numbers mean softer, more luxurious fabric that also comes at a premium price.

Blends matter too. Pure wool offers durability and breathability, and wool-silk blends add luster and drape. Wool-cashmere combinations provide unmatched softness. Each blend affects both performance and cost.

Fabric Mills and Global Sourcing

Premium fabrics come from renowned mills with centuries of expertise. Italian mills like Loro Piana, Ermenegildo Zegna, and Vitale Barberis Canonico command higher prices because of their superior quality control, innovative weaving techniques, and exclusive fiber sourcing.

Standard mills produce perfectly serviceable fabrics, but they lack the refinement, hand feel, and longevity of top-tier options. The difference is immediately noticeable to anyone who’s worn both.

Understanding Fabric Price Differences

Several factors can dramatically increase the cost of a custom suit at the fabric level:

Seasonal fabrics with specialized weaves for summer or winter require different production techniques. Rare fibers like vicuña, cashmere, or sea island cotton are expensive to source and process. Exclusive weaves featuring complex patterns or unique textures demand advanced loom technology and additional labor.

A standard wool might cost $20 per yard, while a luxury blend from a prestigious mill could run $200 per yard or more. Since a suit requires three to four yards of fabric, this quickly adds up.

Craftsmanship and Labor

Hours of Skilled Tailoring

A quality custom suit requires 40 to 60 hours of skilled labor, sometimes more for fully bespoke pieces. This includes pattern drafting, cutting, multiple stages of hand-sewing, pressing, and finishing work.

Hand-sewn elements like pick stitching on lapels, hand-attached collars, and hand-finished buttonholes represent hours of meticulous work. These details aren’t just aesthetic—they allow the garment to move naturally and maintain its shape over years of wear.

Why Skilled Labor Raises the Price

Tailoring is a craft that requires years of training and apprenticeship. Master tailors possess knowledge passed down through generations, understanding how different fabrics behave, how bodies move, and how construction techniques affect the final product.

This expertise comes at a cost. Skilled artisans command higher wages than factory workers operating sewing machines. When you examine bespoke suit pricing, you’re largely paying for human skill, experience, and attention to detail that machines simply cannot replicate.

Quality Control and Finishing

Every seam is inspected. Every measurement is verified. The pressing alone, using specialized equipment and techniques, can take hours. This human-centered quality control ensures problems are caught and corrected before the suit reaches you.

Finishing work includes hand-sewn bar tacks at stress points, clean interior finishing, and careful pressing that shapes the garment’s silhouette. These final touches separate a good suit from an exceptional one.

The Multi-Step Fitting Process

Initial Measurements

Taking accurate measurements is more complex than wrapping a tape measure around your chest. Experienced tailors take dozens of measurements, noting posture, balance, and how you naturally carry yourself. This expertise ensures the pattern accurately reflects your body.

Basted Fittings and Adjustments

Many custom suit makers include at least one basted fitting, where the suit is temporarily assembled so you can try it on. This reveals how the fabric drapes, where adjustments are needed, and whether the pattern achieves the desired fit.

Each fitting round adds to the cost of tailoring, but it’s essential for achieving that perfect fit. Adjustments are marked, the suit is deconstructed, corrections are made, and the process continues until everything aligns perfectly.

Final Fitting and Delivery

The final fitting ensures every detail meets expectations. Sleeve length, trouser break, jacket length—everything is verified before delivery. This commitment to accuracy and refinement protects your investment and guarantees satisfaction.

Customization Features That Add to the Price

Design Details

Every design choice affects both aesthetics and cost. Lapel width and style, vent configuration (single, double, or none), pocket styles (patch, flap, or welt), and button stance all require different construction techniques and materials.

More complex designs demand additional labor and precision, incrementally increasing the custom suit cost.

Interior and Structural Upgrades

What’s inside matters as much as what’s visible. Lavish linings in silk or cupro add luxury and comfort. Full canvas construction, where a layer of horsehair canvas is hand-stitched between the fabric layers, allows the suit to mold to your body over time, creating a more natural drape.

Hand-finished buttonholes, functional sleeve buttons, and reinforced stress points represent additional hours of skilled work that enhance both appearance and durability.

Optional Personalization

Monogramming, custom embroidery, contrast stitching, and specialty trims allow you to make the suit distinctly yours. While these features add personality, they also require additional labor and materials, contributing to the overall suit pricing breakdown.

Tailoring House, Reputation, and Location

Brand Reputation

Established tailoring houses with decades or centuries of experience command premium prices. Their reputation is built on consistent quality, exceptional craftsmanship, and heritage techniques that have stood the test of time.

You’re not just paying for a suit; you’re paying for peace of mind that comes from working with proven experts who stand behind their work.

Regional Pricing Differences

Location significantly impacts pricing. Custom suits made on London’s Savile Row or in New York’s Midtown carry higher price tags due to elevated overhead costs, higher wages, and the prestige associated with these renowned tailoring districts.

Conversely, talented tailors in smaller markets or countries with lower labor costs can offer exceptional value without compromising quality. Understanding these regional differences helps you make smarter purchasing decisions.

Long-Term Value of a Custom Suit

Durability and Repairability

Quality construction means custom suits outlast off-the-rack alternatives by years—sometimes decades. The superior stitching, reinforced stress points, and premium materials resist wear and tear remarkably well.

Additionally, custom suits are easier to repair and alter. Because they’re constructed with traditional techniques rather than fused and glued, skilled tailors can make adjustments, replace linings, or refresh buttonholes without compromising the garment’s integrity.

Fit Longevity

A perfectly fitted suit doesn’t become obsolete when trends shift. Classic proportions and personalized fit ensure your custom suit remains wearable and stylish for years. Minor weight fluctuations can often be accommodated with small alterations, extending the garment’s useful life.

Cost Efficiency Over Time

When you calculate cost per wear, custom suits often prove more economical than repeatedly replacing cheaper alternatives. A $2,000 custom suit worn regularly for ten years costs just $200 annually—far less than buying multiple off-the-rack suits that quickly show wear and never fit quite right.

The higher upfront cost of a custom suit pays dividends in longevity, performance, and sustained confidence every time you wear it.

Myths About Why Custom Suits Are Expensive

Myth: You Only Pay for the Name

While brand prestige contributes to pricing, it’s rarely the primary cost driver. The real expenses come from materials, labor, and the multi-step process required to create a garment unique to you. Reputable brands charge what they do because they deliver measurable quality differences.

Myth: All Suits Are Made the Same

Construction techniques vary dramatically. Fused suits use adhesive to attach layers, while half-canvas and full-canvas suits feature hand-stitched internal structures that move naturally with your body. These construction differences directly impact durability, comfort, and appearance.

Myth: Off-the-Rack Alterations Give the Same Fit

Alterations can improve an off-the-rack suit, but they can’t fundamentally change its structure. Shoulder width, armhole placement, and overall proportions are built into the garment and cannot be meaningfully altered. Custom suits are constructed around your specific measurements from the beginning, achieving a level of fit that alterations simply cannot replicate.

Invest in Quality That Lasts

Now that you understand the true factors behind custom suit cost, from quality fabrics and careful workmanship to custom fittings and long-lasting use, the price starts to make sense.

A custom suit is not an expense; it’s an investment in how you present yourself to the world. It’s confidence sewn into every seam, professionalism expressed through perfect fit, and quality that endures year after year.

Ready to experience the difference for yourself? Schedule a consultation with our expert tailors today and discover how a truly custom suit can transform not just your wardrobe, but also how you feel every time you get dressed. Your perfect fit is waiting.

FAQs

Why do custom suits cost more?

Because they use better fabric, take more time, and involve skilled labor.

Are custom suits worth it?

Yes—if you value fit, comfort, durability, and long-term value.

How long does a custom suit take?

Usually 2–6 weeks.

What affects suit pricing the most?

Fabric quality and labor hours.

Is bespoke better than made-to-measure?

Yes, it starts from scratch with a unique pattern for a more precise fit